Varukorg

Varukorgen är tom!

Varukorgen inkl. moms 0 kr

Elektronisk distribution

Frakt inkl. moms 0 kr

Varav moms (6 %) 0 kr

Varav moms (25 %) 0 kr

Öresutjämning 0 kr

Att betala inkl. moms 0 kr

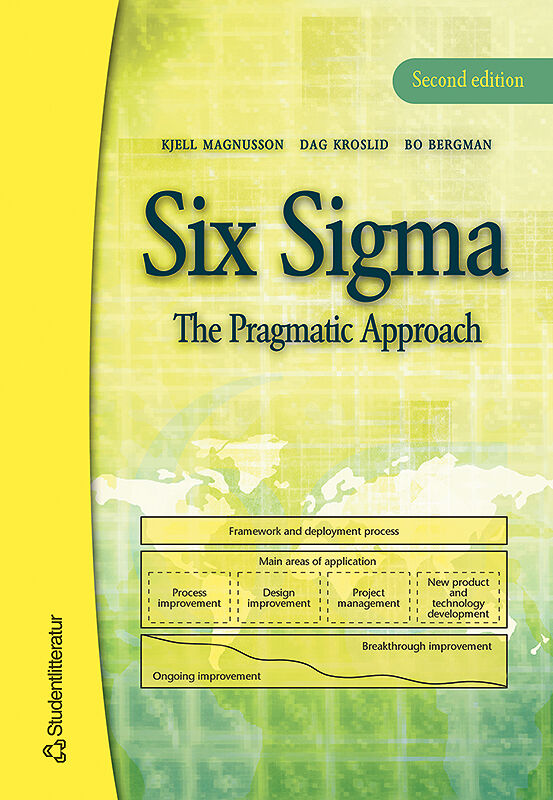

Six Sigma

- Preface

- About the authors

- About the local authors

- 1Introduction

- 2The Six Sigma framework

- 2.1Senior management commitment

- 2.2Stakeholder involvement

- 2.3Training scheme

- 2.4Measurement system

- 2.5Improvement projects

- 3Six Sigma at ABB

- 3.1Six Sigma deployment

- 3.2Improvement projects

- 3.3Results

- 3.4Secrets of success

- 4Introducing Six Sigma in your company

- 4.1The three main deployment approaches

- 4.2Organising for Six Sigma

- 4.3The 12-step deployment model

- 4.4Deployment monitoring

- 4.5Change management

- 5Deployment cases

- 5.1Ericsson, Business Unit Transmission & Transportation Networks, Sweden

- 5.2Agfa, Germany

- 5.3Alfa Laval, Sweden

- 5.4ABB Power Transformer plant, Europe

- 6Involving support functions, suppliers and customers

- 6.1Support functions

- 6.2Supplier involvement

- 6.3Customer involvement

- 7Six Sigma in service organisations

- 8Process improvement

- 8.1The DMAIC process improvement methodology

- 8.2Process development

- 9Case studies – process improvement

- 9.1Light guide fibres – ABB Power Systems

- 9.2Microwave oven leakage –LG Electronics

- 9.3Solder residues on misprinted circuit boards – Ericsson Mobile Systems

- 9.4On-time deliveries – ABB Transformers in China

- 10Design improvement

- 10.1Define

- 10.2Measure

- 10.3Analyse

- 10.4Design

- 10.5Verify

- 11Case studies – design improvement

- 11.1Current breakers – ABB, Germany

- 11.2Washing Machines – Arcelik, Turkey

- 11.3Two design improvement projects on Microwave LINK – Ericsson, Sweden

- 12Project management

- 12.1Generic project management models

- 12.2The enhanced project management model

- 13New product and technology development

- 13.1The new product/technology development process

- 13.2Integrating Design for Six Sigma

- 14Frequent questions – pragmatic answers

- Appendices

- Appendix A– GE Quality 2000: A dream with a plan

- Appendix B– Motorola, the cradle of Six Sigma

- Appendix C– The European Six Sigma Club

- C.1 History

- C.2 Charter and Objectives

- Appendix D– Black Belt issues

- D.1 A Black Belt job description

- D.2 A Black Belt course – a detailed description of content

- Appendix E– Measuring process performance (capability analysis)

- E.1 The regular case with long-term data

- E.2 The special case of short-term data

- E.3 Continuous characteristics and discrete characteristics

- E.4 Consolidating process performance measurements

- E.5 Risks concerning historical data

- E.6 Converting dpmo values to sigma values

- E.7 Set goals and achieved goals

- Appendix F– Some basic statistical topics

- F.1 Common cause and special cause variation

- F.2 The concept of predictability

- F.3 Control limits and specification limits

- F.4 The importance of logarithmic values

- F.5 Some probability distributions

- F.6 Total, Within Subgroup and Between Subgroups

- Appendix G– ANOVA and ANOM

- G.1 Analysis of variance (ANOVA)

- G.2 Analysis of means (ANOM)

- Appendix H– Regression Analysis

- H.1 An introductory example

- H.2 The underlying theories

- H.3 Example from application in a support process

- Appendix I– Factorial experiments

- I.1 An introductory example

- I.2 Different designs

- I.3 Calculate and analyse effects

- I.4 Prediction model and diagnostics

- I.5 Fractional factorials

- I.6 Repeated experiments

- I.7 Randomisation

- I.8 Experiments with centre points

- I.9 The seven generic steps

- Appendix J– Quality function deployment (QFD)

- J.1 The eleven elements of each matrix (rooms of the house)

- J.2 The four phases of transformation in detail

- Appendix K– The seven lean tools

- Appendix L– List of symbols

- Appendix M– Reference tables

- M.1 Normal distribution table P(X Š z) when X is N(0,1)

- M.2 Poisson distribution table P(X > x) when X is Po(m)

- M.3 F distribution table

- M.4 Probability plotting position, Fg

- M.5 Constants for control charts

- M.6 Factorial experiments – commonly used design matrices

- M.7 Values of H for ANOM charts

- M.8 Transformation table, sigma values and dpmo values

- References

- A selection of recommended literature

- Index

Information

- Författare:

- Kjell Magnusson Bo Bergman Peter Häyhänen Dag Kroslid Donald Findlay Mills

- Språk:

- Engelska

- ISBN:

- 9789144028033

- Utgivningsår:

- 2000

- Revisionsår:

- 2003

- Artikelnummer:

- 7567-02

- Upplaga:

- Andra

- Sidantal:

- 480